Coconut Waste Changes to Grace for Poor Farmers

Dr. Walter Bradley says he may never retire, now that he’s found a way to help people in poor countries while turning agricultural waste into useful materials. For two decades his work in materials science helped the defense and aerospace industries. Now, as Distinguished Professor of Mechanical Engineering at

Baylor University in Waco, Texas, his team is exploring the uses of coconut fiber and pith milled from the coconut husk and the hard coconut shell – to ultimately help impoverished coconut farmers in equatorial countries.

Eleven million coconut farmers around the world make only 10 cents for each coconut, and typically sell only 5000 a year, giving an income of less than $2 US/day. Demand for coconut oil plunged in the 90s due to health concerns, dramatically reducing the price for the white coconut meat from which the oil is pressed. While consumers only see the hard brown nut in the store, or bags of shredded coconut or cans of coconut milk, there are actually many other parts we don’t see that are mostly discarded, and that amounts to something on the order of 20 billion pounds a year of agricultural waste. There’s a lot of it available, and it’s a renewable resource.

It was a situation ripe for exploration that came to Dr. Bradley’s attention when a formal doctoral student of Dr. Bradley’s from Papua New Guinea asked to spend his sabbatical working with him. Dr. Bradley stipulated that the engineer, from a poor country himself, help him find a new project that would help poor people in Papua New Guinea. Since then, this Texas native has ventured to the Philippines, Indonesia, and Brazil to investigate the source of the natural materials that he would try to turn into something valuable to benefit everyone involved.

And he has.

His team is creating new materials ultimately used to line automobile trunks. They are developing more sustainable plastic composites that can be used in children’s toys. The possibilities for this underutilized natural resource are astounding, he has learned since he first started his investigation of the uses for coconuts a few years ago.

“I said, ‘Let’s go figure out what the properties of the shell and the husk are and what we can use them for,’” he explained. “They have extremely interesting properties that make them very attractive for a wide variety of applications, which we’re exploring. Coconut fiber has about 25% elongation - that means you can stretch it by 25% before it breaks – partly because its function in nature is to cushion the impact of the nut when it falls. When it hits the ground, it’s going about 45mph, so it has to have tremendous energy-absorbing capability. Most natural fibers are from stems and branches that don’t need that much elongation – 2-3% at the most.” Unlike other natural fibers, it’s also burn resistant and resistant to the development of odor.

Coconut fiber has high lignin content. “Other natural fibers also have odor problems because the microorganisms eating on the fibers release various gases. I put 150 pounds of coconut husk outside of my house where it gets hit by the sprinkler and sun and there’s no smell,” Dr. Bradley says.

To get a closer look at the fiber, Dr. Bradley uses a low vacuum SEM, the JEOL JSM-6610LV, which was installed in early 2011. A Microtest tensile stage holds the samples in place and allows for testing the tensile properties of the fiber to determine at what point it will break. Dr. Bradley explains, “Coconut has a large diameter fiber - about 160 microns. Most natural fibers are 40-50 microns so it’s four times the diameter and the geometric component of stiffness is 256 times more, which means the fibers have a high flexural rigidity.”

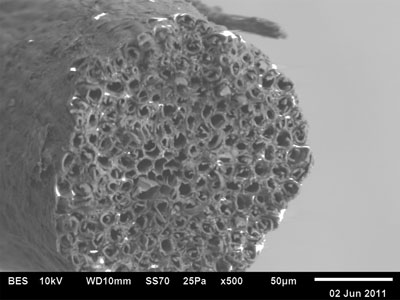

The team at Baylor uses the SEM to study the fiber surface topography – rougher fibers are more adherent when they are used in a polymeric matrix. The SEM also helps them examine the interior of the fiber. “If you carefully break a fiber and look on end, the fiber is not solid, it’s porous, like a honeycomb structure,” Dr. Bradley says. “It has wonderful properties. It has a low mass density, yet it has a high degree of strength and stiffness. It’s 60% solid material and 40% voids. When we first started working with it we couldn’t figure out why our composites were so much lighter. It has lower density because coconut fiber has lots of long tubulars running the length of the fiber on the inside. It probably has, within that fiber, 60-80 tubulars that are very, very small. One of nice things about using the JEOL SEM is that we can run it in low vacuum mode. We have to do that because the fibers we’re looking at are never completely dry and we prefer not to coat them. Some of the details would be skewed. It’s perfect for working with natural materials in low vacuum mode and we get really nice images. Sometimes we do coat the fiber for secondary electron imaging, but it’s almost impossible to work in high vacuum with these samples.”

The shell of the coconut is amazing as well. “It’s four times harder than maple and ten times harder than pine. It also has high lignin content so it doesn’t burn very easily – there’s no mold or smell or pests. We grind it into a very fine powder and incorporate that powder into engineering plastic like polypropylene. We can easily double the stiffness of polypropylene with about 30% coconut shell filler. Today the price of poly is about $1 pound and we can obviously get significant value from coconut shell powder, because we’re we are replacing polymeric resin that’s fairly expensive with with a filler that is less expensive and will double the stiffness of the composites – that’s not a hard sell.”

“It’s staggering how many trees there are around the world. There are 50 billion coconut trees and it grows to maturity and is producing fruit within 3-7 years and goes on for 70 years. A healthy tree produces 100 coconuts a year,” Dr. Bradley explains.

During his travels to investigate the source of all this raw material, he’s often asked, “What are you doing working on coconuts since they don’t grow in the US?” His reply goes back to his original intention. “My goal is not to work on a cash crop in the US, but instead on one owned by the poor people. I could have worked on palm but it’s mostly owned by palm plantations so I decided not to, it’s not worth not retiring for. We’re really interested in agricultural waste that’s poorly utilized and owned by poor farmers. There are quite a few choices out there and we will find other things like that.

“We work closely with business people who have shared goals. It will be a ‘for profit’ business but we want it to be one in which we try to be sure everybody in the food chain gets treated in a generous way. We want to be able to add value to the community and take some of the growth that comes out of this and provide vouchers for children to go to school. At the moment we’re getting materials from the Philippines and Indonesia, and potentially from Brasil, the Caribbean, and Africa, and we have good contacts in India and Sri Lanka that we’re working with. Science is the means by which we’re trying to do something that will use environmental resources more carefully, sustainably, while helping poor people in developing countries to have jobs and opportunities and particularly help children go to school. It’s one of these win-win-win projects.”

JEOL is pleased to have been selected to provide the electron microscope that Dr. Bradley uses in his research. We first met him when he was at Texas A&M University. “The only microscopes I ever worked on were JEOL so I had a long and very positive history,” he says. “One of things we want to be able to do is make actual composite samples then break them and make videos at high magnifications to see how the composite fails. When we do that we can figure out exactly what’s causing it to break and what we can do to make it even better yet. We can look at bigger samples and the loading stage allows us to put sample in chamber and actually test it.

“When I finished my career I wanted it to be something that really ended well. Our engineering services are going where there is no discretionary income, and a little bit of technology can have dramatic increase in quality of their lives.”