Advances in TEM Research at University of Pennsylvania Singh Center of Nanotechnology

While the pandemic may have forced many researchers and students to remain in situ, the

Singh Center for Nanotechnology at the University of Pennsylvania has continued to advance the field of in situ Transmission Electron Microscopy. Industry collaborators and fellow researchers recently published an important new paper concerning how solid electrolyte materials operate and fail in potential future advanced batteries for transportation applications. And even though professors and students may not have the more traditional in-person experience, special projects have resulted in useful resources that any level of in situ TEM user will appreciate.

Collaboration on Solid State Lithium Ion Battery Development

Under the direction of Professor

Eric Stach, who specializes in the development of advanced in situ and operando imaging and characterization techniques (and is also Chief Technology Officer of

Hummingbird Scientific, provider of TEM sample holders), the lab’s focus on Lithium Ion Battery technology resulted in a paper published in Matter, in December 2020,

In Situ Investigation of Chemomechanical Effects in Thiophosphate Solid Electrolytes - ScienceDirect. The work is a collaboration between the University of Pennsylvania, Vanderbilt University, Toyota Research Institute of North America, and Argonne National Laboratory.

Stach says the team has been “looking at solid state electrolyte materials with Toyota Research Institute of North America. They are interested in solid state batteries because they are less likely to have issues with lithium dendrites, which can lead to battery failures. The group at Toyota Research Institute of North America has been very aggressively working on the appropriate material to use as the solid electrolyte. Our collaborative approach has been taking advantage of Hummingbird’s ability to bring in lithium on a mobile probe. The idea is you have created a TEM sample that consists of electrode and solid electrolyte and then you bring in lithium on a mobile probe (

Hummingbird Scientific) to touch this and complete the battery. You then drop a voltage which drives the lithium through the solid electrolyte into the anode. We can do all that in the microscope.”

He adds, “I’ve worked with Nik (

Nikhilendra Singh of Toyota Research Institute of North America) before – he knows how to use TEM well and is able to frame his problems around what the technique can accomplish. At the Singh Center, researchers like Nik can access forefront capabilities. He comes well prepared, and we can quickly provide the data that he needs.” Nik has been a corporate researcher using the facilities at Singh for the past decade. Singh center schedules time for him and Stach dedicates a student to the project, in this case Jay Horwath, a 4th year PhD student.

Catalyst Research

In keeping with the energy theme in research, the lab is also

investigating catalysts with

Ke-Bin Low at BASF.

“He has hired a post doc in our group to advance their efforts,” Stach explains. “We’re doing high temperature, high pressure analysis in the F200 and NEOARM to understand issues in heterogeneous catalysis.”

Low gave some insight into this project: “At BASF, we fulfill our social responsibility for environmental protection through innovation in catalysis and carbon management programs. Transmission electron microscopy is a key characterization technique for elucidating material structure-property relationships. The collaboration with University of Pennsylvania allows us to advance our product knowledge by studying them under realistic environmental stimuli using their state-of-the-art in-situ TEM facility.”

TEM Resources for Advanced Research

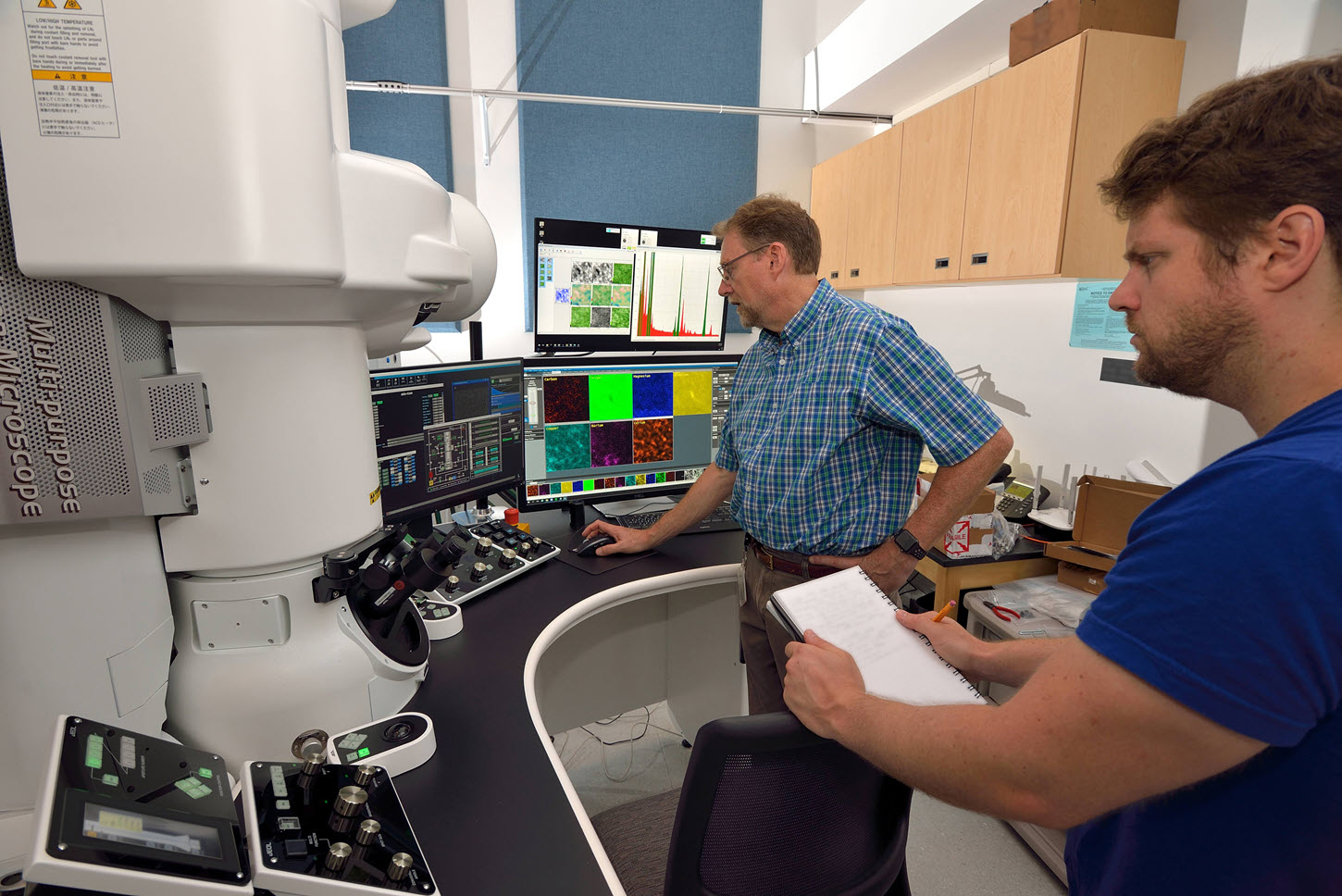

The group has done all the work using the

JEOL F200 TEM, which is the workhorse TEM at the center, while the specialized

JEOL NEOARM is reserved for STEM and EELs.

“The F200 is a beautiful instrument; we use it for lots of stuff. The thing about the NEOARM is that although you can do TEM, we don’t do us it for that as often because it’s so aligned and perfect in STEM mode you don’t want to fool with it. We do a lot of work over on the F200 that takes advantage of the versatility of that machine, then take it to the NEOARM for STEM where you want the extra resolution.”

Eric Stach

The two microscopes are in operation or available for scheduling 18 hours a day. When planning for the acquisition, he says, “One microscope wasn’t going to be enough based on our known demand at Penn and in the region.” The facility not only benefits students and researchers, it also serves as a Center of Excellence demo site for JEOL.

Student Project Advances Understanding of Unsupervised Image Segmentation and Machine Learning

The center is the microscopy resource for the University’s Materials Science and Engineering program, and even though classes are mainly remote, Prof. Stach is presently teaching students on TEM theory and posting video laboratories. One notable student, Leena Vyas, worked closely with Stach’s assistant Jay Horwath who published

Understanding important features of deep learning models for segmentation of high-resolution transmission electron microscopy images | npj Computational Materials (nature.com) in July. Stach explained that in the past several years, his group has been developing methods for quick, automated image analysis using "unsupervised image segmentation".

Horwath had collected multitudes of data on the microscopes showing in real time how particles change size and shape. He figured out all the machine learning, and with Vyas’s assistance, the pair were able to create an online tutorial and step-by-step guide for machine learning,

Tutorial on Unsupervised Image Segmentation for Electron Microscopy.

“I encouraged Vyas to write up the process by which you do it then simplify it. I know for the last twenty years I’ve been looking for the same information and never could find it. She did a nice job putting it together. I knew that a lot of people could use this – last I looked

the post on LinkedIn about this had was fourteen thousand views,” says Stach. Vyas had only completed her Freshman year when she took on the project.

This tutorial answered a long-time need. “Every time you have a brand-new student come into your office and ask ‘What software do I use to count the particles?’, you have to answer, ‘There isn’t one. Get a piece of paper and a pencil and figure it out. It’s kind of a right of passage. Everyone has to go through the process but it’s something a computer can now do. We recognized that machine learning should be sophisticated enough to do this but takes a fair amount of work to figure out the process. This tutorial should save lots of researchers a lot of time.” Stach says there is now a “

comprehensive webpage that provides a step-by-step guide, including links to Python notebooks that you can utilize and example data to follow along.”

Understanding how individual particles interact has long been a goal for physicists. Today’s massive amounts of data from atomic resolution TEMs is more accessible now, but with the help of the tutorial more information is easily obtained.

While no one could have foreseen the sudden change in our lifestyles in 2020, innovation and resiliency prevail with the team at the Singh Center.